Description

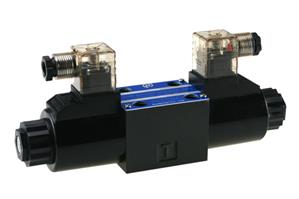

The control element used to change the flow direction of the medium in the pipeline is called directional control valve. It consists of a spool inside a cylinder which is mechanically or electrically controlled. The movement of the spool restricts or permits the flow, thus it controls the fluid flow.

Classification of Directional Valve

1. By the flow direction of the medium in the pipeline, it can be divided into one-way control valve and reversing valve. The valve which only allows the medium to flow in one direction is called one-way control valve, such as one-way valve and shuttle valve. The valve that can change the flow direction of the medium is called the reversing valve, such as the ordinary two-position two-way valve, two-position three-way valve, two-position four-way valve, and three-position four-way valve.

2. By mode of control, it can be divided into solenoid valve, mechanical valve, pneumatic control valve, and manual control valve. Among them, the solenoid valve can be sub-divided into single and double solenoid valves. The mechanical valve can be sub-divided into ball valve, roller valve and so on. The pneumatic control valve can be sub-divided into single and double pneumatic control valves, and manual control valve can be sub-divided into manual valve and foot valve.

3. By working principle, it can be divided into direct acting valve and pilot valve. The direct acting valve can directly reverse the direction by means of manpower, electromagnetic force or aerodynamic force. The pilot valve is composed of two parts, the pilot valve and the valve body, wherein, the pilot valve drives the spool inside the valve body to change the direction.

4. By working position of the reversing valve spool, it can be divided into two-position valve and three-position valve.

5. By the number of oil ports on the valve, it can be divided into two-way valve, three-way valve, four-way valve etc.

Advantages of Directional Control Valve

1. Excellent oil-immersed solenoid actuation design

2. High energy use efficiency to reduce the use cost

3. Reduce the temperature rise, increase the service life to save maintenance cost

4. Directional valve can be applied under high pressure (315bar)

5. Special coil assures safe operation

6. Water-proof and dust-proof electrical installation

7. Easy to mount

Note of Directional Control Valve

1. The applicable hydraulic oil

(1) Petroleum base hydraulic oil - equivalent to ISO Vg32, Vg46 and Vg68 oil

(2) Synthetic hydraulic oil - phosphate ester hydraulic oil

(3) Water base hydraulic oil – water-glycol hydraulic oil

2. Oil viscosity and oil temperature

Recommended viscosity range is 15 to 400mm2/s, the temperature range is -15 to 70 DEG C

3. The solenoid coil should meet the ISO4400 standard

4. The mounting surface should meet the ISO4400 standard

Tag: Directional Control Hydraulic Valve | One-way Control Valve | Pneumatic Control Valve | Manual Control Valve

English

English

Español

Español

Français

Français